Kesrec and VMT Plastic – A Circular Economy Partnership

How Kesrec and VMT Plastic are Redefining Sustainability in Plastics Manufacturing

At Kesrec, our mission is to close the loop on plastic waste and empower industries with high-quality, sustainable materials. Our collaboration with VMT Plastic, a family-owned subcontractor specializing in technical plastic products, highlights the potential of a circular economy in action.

Our partnership with Kesrec enables us to incorporate over 50% recycled materials into our production, contributing significantly to our environmental goals.”

– Vesa Tuominen, CEO, VMT Plastic

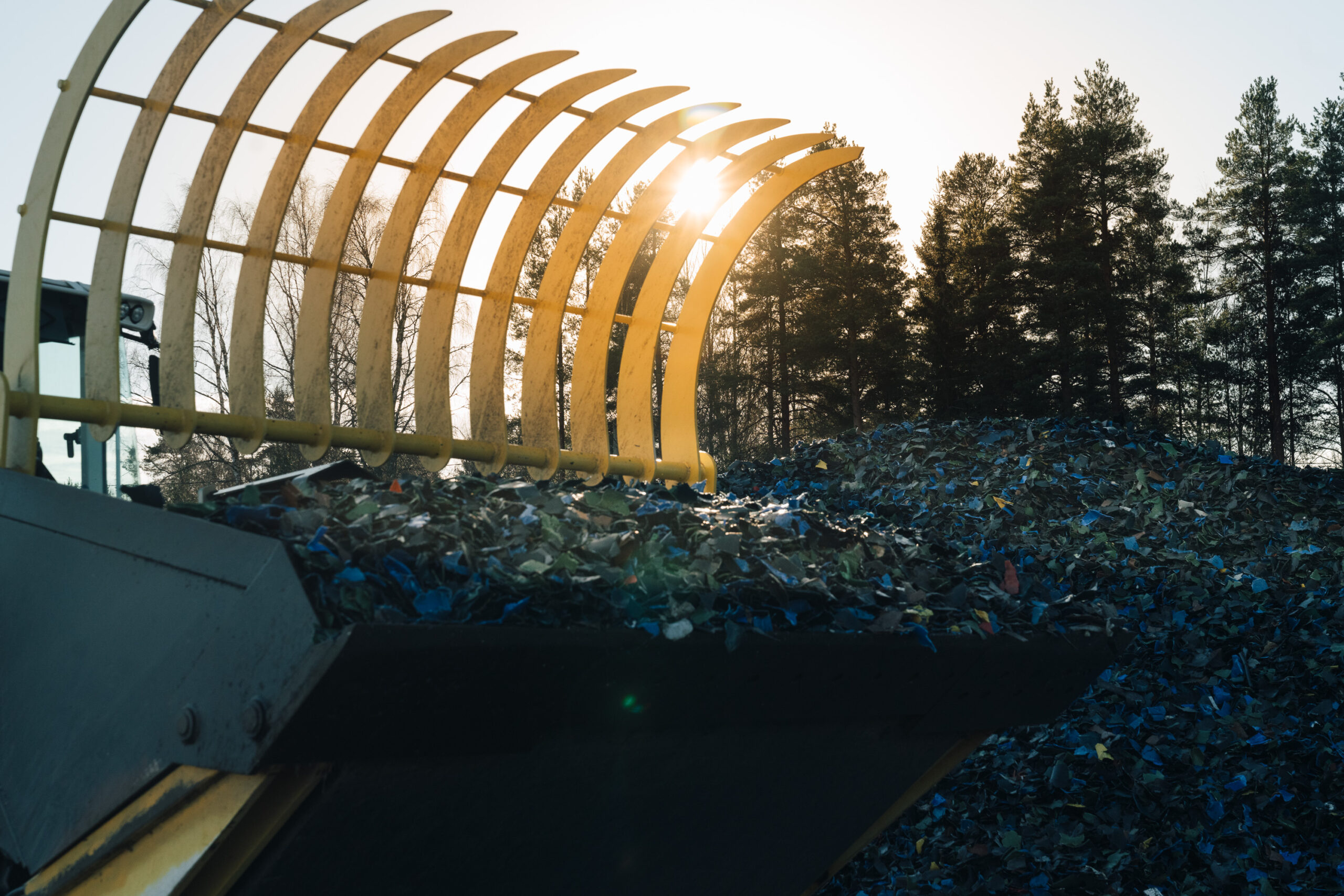

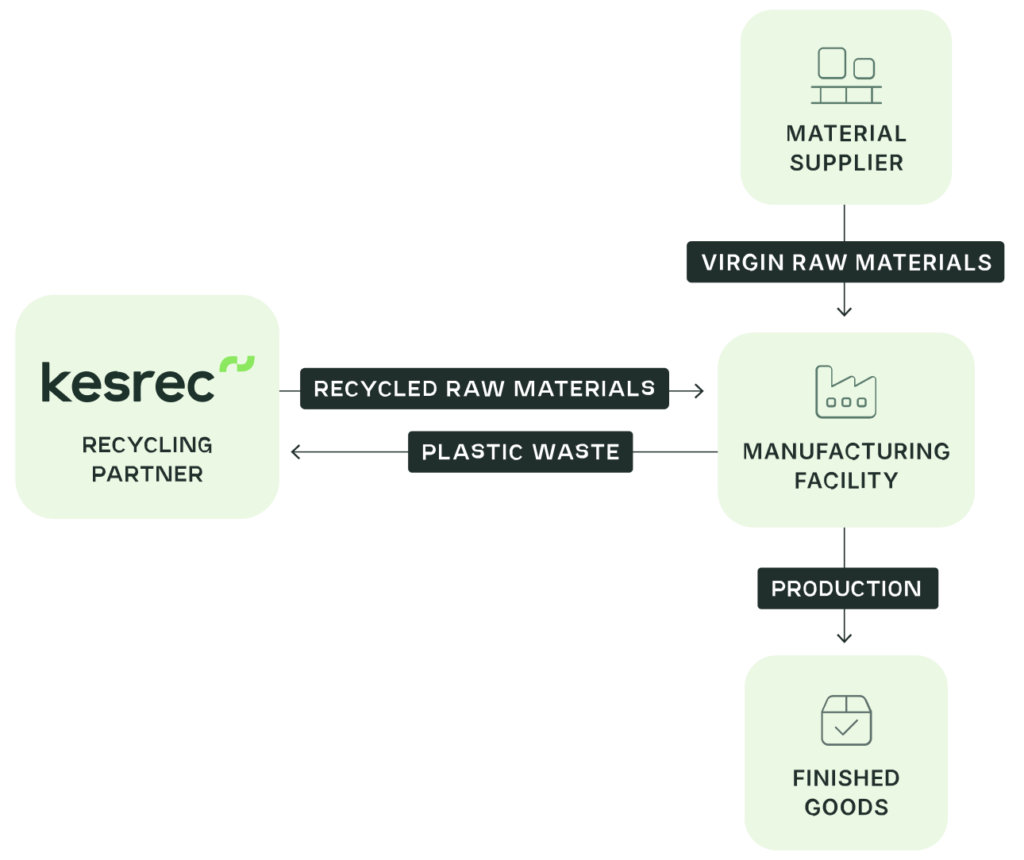

Kesrec processes discarded and defective plastic products, along with industrial scrap, into premium recycled granules. These materials form the backbone of VMT Plastic’s operations, where they are transformed into high-performance technical plastic products using blow molding and injection molding techniques.

Seamless Integration with Circular Practices

At the core of this partnership lies toll granulation. Kesrec takes VMT Plastic’s production waste, processes it into reusable granules, and returns these materials for new product manufacturing. This not only reduces material waste but also cuts down on the reliance on virgin plastics, creating a win-win solution for both businesses.

Driving Results: Impact on Sustainability

- 50%+ Recycled Material Usage: VMT Plastic has achieved over 50% recycled material usage across its operations, and with Kesrec’s support, this figure is on track to increase.

- Reduced Carbon Footprint: The partnership has significantly minimized CO₂ emissions by diverting plastic waste from landfills and reducing the need for new raw materials.

Why This Matters

As environmental awareness grows, customers are increasingly prioritizing companies that demonstrate a commitment to sustainability. Businesses like VMT Plastic, which integrate sustainable practices into their operations, are positioned as industry leaders in this shifting landscape. Their dedication to using recycled materials and minimizing waste not only supports global sustainability goals but also aligns with consumer expectations for responsible production.

By sourcing high-quality recycled materials from Kesrec and reprocessing their own production waste, VMT Plastic has established itself as a forward-thinking manufacturer. This approach allows the company to meet rising demand for eco-friendly products while maintaining a competitive edge in the market. Together, Kesrec and VMT Plastic exemplify how innovation and sustainability can drive success, paving the way for a greener future in the plastics industry.

Future Goals: Scaling Sustainability

The partnership between Kesrec and VMT Plastic has delivered measurable results, significantly advancing sustainability goals for both companies. VMT Plastic has successfully integrated over 50% recycled materials into its manufacturing processes, with ambitions to increase this percentage further. By utilizing Kesrec’s high-quality recycled granules, VMT Plastic has reduced its dependency on virgin plastics, aligning with growing market demands for eco-friendly products. This collaboration not only minimizes material waste but also helps lower carbon emissions by diverting plastic from landfills and reducing the environmental footprint of their operations.

Beyond the numbers, this partnership highlights the broader impact of circular economy practices on the plastics industry. By combining Kesrec’s expertise in plastic recycling with VMT Plastic’s advanced manufacturing capabilities, both companies demonstrate how sustainable solutions can be seamlessly integrated into industrial operations. Customers increasingly prioritize environmental values, and by leveraging recycled materials, VMT Plastic has positioned itself as a leader in sustainable manufacturing. Together, Kesrec and VMT Plastic are proving that reducing waste and advancing innovation can go hand in hand, creating a blueprint for others to follow.

Conclusion

Our partnership with VMT Plastic is a shining example of what’s possible when industries come together to prioritize sustainability. At Kesrec, we’re not just transforming plastic waste—we’re shaping a cleaner, greener future.